Brief Description Of Structural Parts Production Process

1. Pretreatment stage

The first step in the production of structural parts is the pretreatment stage. At this stage, it is necessary to carry out production planning, select suitable raw materials, determine the size and shape of the structural parts, etc. The production plan is the basis and guidance for the production of structural parts. It includes production volume, production time, production goals, etc. Selecting suitable raw materials is the key. The raw materials need to meet the strength, corrosion resistance, wear resistance and other requirements of the structural parts. Determining the size and shape of the structural parts requires considering the function and use environment of the structural parts.

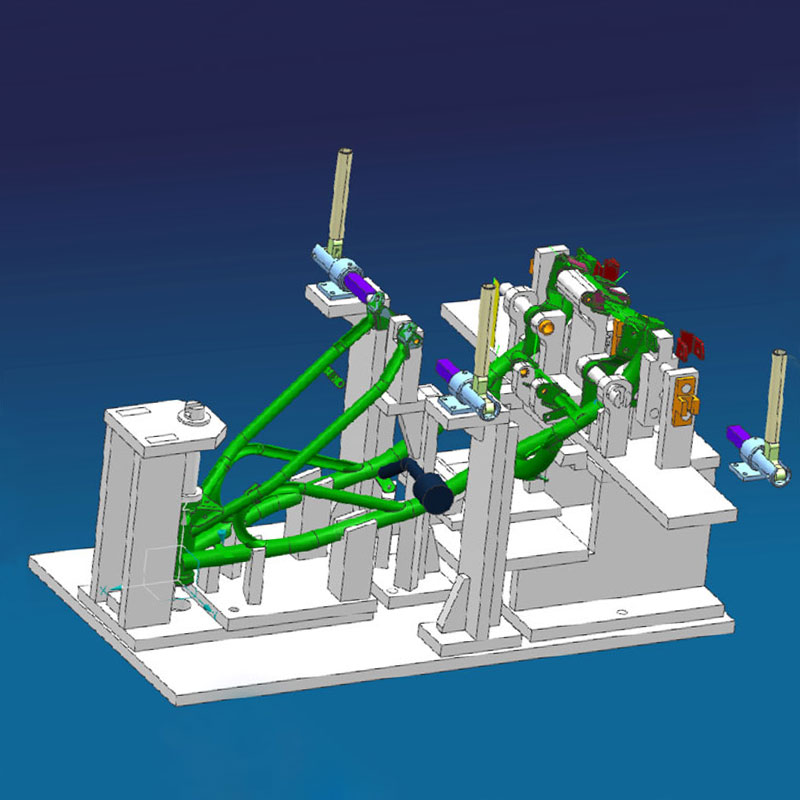

2. Processing and manufacturing stage

The processing and manufacturing stage is the core stage of structural parts production. At this stage, cutting, stamping, bending, welding and other processes are required. These process technologies are the key to producing high-quality structural parts and need to rely on various advanced processing equipment and tools to complete.

(1) Cutting processing

Cutting processing is the process of cutting raw materials into the required size and shape. The commonly used tools for cutting are rotary tools or blades, mainly lathes, milling machines, drilling machines and other equipment.

(2) Stamping processing

Stamping is the process of extruding metal sheets or strips into the required shape. The main stamping technologies include flat die stamping, pendulum pressure stamping, etc.

(3) Bending Process

Bending is the process of bending metal materials into the desired shape. Bending technologies mainly include manual bending, metal plate bending machine and metal plate bending machine.

(4) Welding Process

Welding is the process of combining two or more metal materials into one by melting or pressure. Welding technologies include manual welding, gas welding, electric welding, laser welding, etc.

3. Surface treatment stage

Surface treatment is to increase the corrosion resistance and aesthetics of structural parts, including spraying, electroplating, hot-dip galvanizing and other processes.

4. Inspection stage

The inspection stage conducts quality inspection and testing on the produced structural parts, including appearance inspection, size inspection, function inspection, etc. After passing the inspection, the structural parts can be packaged and sold.